Grid Measurement dialog

This dialog appears when you click the Grid

Measurement button on

either the Graybox dialog or the Define Bar Code dialog. Use it to define

the location of graybox and software bar code grid evaluation regions

and clip regions in your application.

The title of the Grid Measurement dialog depends on

the operation you are performing:

- Create New Grid

dialog – This is the title when you do one of the following:

- Enter a new

output field, select the Graybox Tool or Bar Code Tool, and then select

the Grid Measurement button.

- Select an existing

field or grid, select the Graybox Tool or Bar Code Tool, and then select

the Grid Measurement button.

- Have no grid

selected, select the Graybox Tool or Bar Code Tool, and then select the

Grid Measurement button.

You can then enter the Grid Measurement values for

the new graybox or bar code grid.

- Modify

Grid Measurement dialog

– This is the title when you do the following:

- Select a graybox

or software bar code grid and then select, in order, the Edit Selected

Grid button and the Grid Measurement button, in the Graybox dialog or

in the Define Bar Code dialog.

- Have no grid

selected, select the Graybox Tool or Bar Code Tool, draw a grid in the

grid definition area, and then select the Grid Measurement button.

You can then modify the Grid Measurement values

for the graybox or bar code grid.

- View

Grid Measurement dialog – This is the title when you select a graybox

or software bar code grid and then select the Grid Measurement button,

in the Graybox dialog or in the Define Bar Code dialog, without first

selecting the Edit Selected Grid button. You can view the Grid Measurement

values but you cannot modify them because the graybox or bar code grid

is therefore not in edit mode.

TIP: If you are

using an imaging scanner, you may find it more convenient to draw graybox

and software bar code grid evaluation regions and clip regions directly

in the grid definition area. See Creating

a Graybox Grid and Bar Code Implementation

for additional information.

Grid Location

This is reference information. The values in this area

cannot be changed.

- Field

–shows the name of the field this graybox or software bar code

grid is appended to.

- Sheet

–shows the sheet number on which this graybox or software bar

code grid is located.

- Side

–shows the side of the sheet, Top or Bottom, on which this

graybox or software bar code grid evaluate region is located. The side

on which the clip region is located is not displayed.

Unit of Measurement

Select the measurement system used for defining the

exact coordinates for location and size of the graybox or software bar

code grid. The selection made here is used in the Evaluate Region and

Clip Region, X and Y

Region Position areas. In all cases, the origin point is the intersection

of the leading edge and

of the form.

NOTE for OpScan iNSIGHT

2/4 (with Imaging) Scanner Users:

As absolute Units of Measurement (.001 in and .01 mm) is an advanced feature

of ScanTools Plus software, utilizing the full capabilities of OpScan

iNSIGHT 2/4 (with Imaging) scanners, you should ensure that your scanner

includes the advanced features in scanner Manufacturing Level ML013 or

greater.

To verify your scanner Manufacturing Level, look at the serial number label

on the back of the scanner and read the “ML” number.

If the ML number is less than ML013, call Scantron Customer Support at

800-338-5544 to arrange to have your scanner enhanced to this Manufacturing

Level.

For International users, contact your local sales representative.

Select one of the following values:

- Cell/TM

Position – Read cell and

timing mark numbers. Locations are measured to specified Cell/TM

response position centers and then clip and evaluate regions are automatically

enlarged by ScanTools to include complete OMR response positions.

- .001 in

– Thousandths of an inch. Locations are measured from the origin point

in thousandths of an inch.

- Hybrid .001 in

– A combination of read cell and timing mark numbers and thousandths of

an inch. Base locations are measured to specified Cell/TM response position

centers and then clip and evaluate regions are enlarged by the amount

you specify, defined in thousandths of an inch. When this is selected,

an additional Hybrid control, Hybrid Offset, appears in this dialog.

- .01 mm –

Hundredths of a millimeter. Locations are measured from the origin point

in hundredths of a millimeter.

- Hybrid .01 mm

– A combination of read cell and timing mark numbers and hundredths of

a millimeter. Base locations are measured to specified Cell/TM response

position centers and then clip and evaluate regions are enlarged by the

amount you specify, defined in hundredths of a millimeter. When this is

selected, an additional Hybrid control, Hybrid Offset, appears in

this dialog.

CAUTION: There

are special Unit of Measurement considerations for OpScan iNSIGHT 2/4

(with Imaging) scanners, forms without timing marks, iNAME

scan-time archiving, OMR/merge horizontal adjustment, ScanFlex, and user

exits. See information below regarding these SPECIAL

CASES.

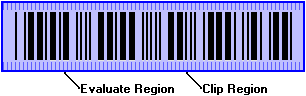

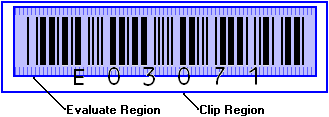

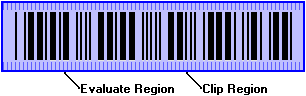

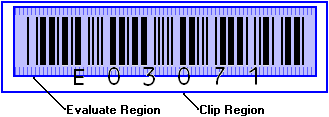

Clip and Evaluate Regions

Select the dependency of the Clip and Evaluate regions

of the graybox or software bar code. The clip region is the graphic

of the graybox or software bar code and is used for viewing in the post-scan

editor or for archiving as a separate graphic file. The evaluate region

is the area of the graybox or software bar code that is evaluated

at scan time for the presence of data. Graybox data presence is based

on the Cutoff Value defined in the Graybox dialog. Software bar code data

presence is based on decoding defined in the Define Bar Code dialog.

Clip Region Tracks

Eval Region

– the Clip Region is identical to whatever is entered in the Evaluate

Region. You cannot enter values for the Clip Region.

Clip Region is

Unique – each region is independent and can differ from the other.

This choice allows you to enter different values for the Evaluate Region

and Clip Region.

- If the Clip

Region is on the same sheet side as the Evaluate Region, you can define

the position in this dialog or you can draw the Clip Region in the grid

definition area. You can use any Unit of Measurement.

- If the Clip

Region is not on the same sheet side as the Evaluate Region, you must

draw the Clip Region in the grid definition area. You must use Cell/TM

or Hybrid Unit of Measurement.

CAUTION: If

the clip region of an ICR/OCR graybox does not fully encompass the evaluate

region,

will not be saved for that ICR/OCR graybox.

Evaluate Region

Region Position

Use these controls to define the X and Y

coordinates for two opposite corners of the evaluate region of the graybox

or software bar code. This defines the exact location and size of the

evaluate region. For the Top side of a sheet, enter X and Y

coordinate values for Upper Left and Lower Right corners. For the Bottom

side of a sheet, enter X and Y

coordinate values for the Upper Right and Lower Left corners.

X (Cell or .001"

or .01 mm) – enter the value that represents the location of the

corner of the evaluate region, along the X axis of the form. This is the

read cell number, or number of inches or millimeters from the guide edge

of the form. The unit of measure used depends on the Unit of Measurement

selected. The minimum values are 1 for Cell and 0 (zero) for .001"

or .01 mm. We recommend using minimum

values of 1 for Cell, 50 for .001", and 120 for .01 mm.

Y

(TM or .001" or .01 mm) – enter the value that represents

the location of the corner of the evaluate region, along the Y

axis of the form. This is the timing mark number, or number of inches

or millimeters from the leading edge of the form. The unit of measure

used depends on the Unit of Measurement selected. The minimum values are

1 for TM and 0 (zero) for .001" or .01 mm. We

recommend using minimum values of 1 for TM, 65 for .001", and 155

for .01 mm.

Upper Left/Upper Right – these controls refer to which

corner of the region is being defined.

Lower Right/Lower

Left – these controls refer to which corner of the region is being

defined.

CAUTION: If

a value less than the recommended minimum value is used as a value for

X or Y with .001" or .01 mm units of measurement, there is a possibility

the image will contain black (and possibly garbage) from the buffer.

Hybrid Offset

This appears only if the Unit of Measurement

selection is Hybrid .001 in or

Hybrid .01 mm. Use this to enlarge

the Evaluate Region. The base location of the region is defined by read

cell and timing mark number, measured to response position centers. You

can then enlarge the region in increments of either thousandths of an

inch or hundredths of a millimeter on both the X and Y axes.

+X (.001"

or .01 mm) – valid values are 0 – 1000 for thousandths of an inch,

and 0 – 2540 for hundredths of a millimeter.

+Y (.001"

or .01 mm) – valid values are 0 – 1000 for thousandths of an inch,

and 0 – 2540 for hundredths of a millimeter.

Upper Left/Upper Right – these controls refer to which

corner of the region is being enlarged.

Lower Right/Lower

Left – these controls refer to which corner of the region is being

enlarged.

Clip Region

Region Position

Use these controls to define the X and Y coordinates

for two opposite corners of the clip region of the graybox or software

bar code. This defines the exact location and size of the clip region.

For the Top side of a sheet, enter X and Y coordinate values for Upper

Left and Lower Right corners. For the Bottom side of a sheet, enter X

and Y coordinate values for the Upper Right and Lower Left corners. This

is not available if Clip Region Tracks Eval

Region was selected, above.

X (Cell or .001"

or .01 mm) – enter the value that represents the location of the

corner of the clip region, along the X axis of the form. This is the read

cell number, or number of inches or millimeters from the guide edge of

the form. The unit of measure used depends on the Unit of Measurement

selected. The minimum values are 1 for Cell and 0 (zero) for .001"

or .01 mm. We recommend using minimum

values of 1 for Cell, 50 for .001", and 120 for .01 mm.

Y (TM or .001"

or .01 mm) – enter the value that represents the location of the

corner of the clip region, along the Y axis of the form. This is the timing

mark number, or number of inches or millimeters from the leading edge

of the form. The unit of measure used depends on the Unit of Measurement

selected. The minimum values are 1 for TM and 0 (zero) for .001"

or .01 mm. We recommend using minimum

values of 1 for TM, 65 for .001", and 155 for .01 mm.

Upper Left/Upper

Right – these controls refer to which corner of the region is being

defined.

Lower Right/Lower Left – these controls refer to

which corner of the region is being defined.

CAUTION: If

a value less than the recommended minimum value is used as a value for

X or Y with .001" or .01 mm units of measurement, there is a possibility

the image will contain black (and possibly garbage) from the buffer.

Hybrid Offset

This appears only if the Unit of Measurement

selection is Hybrid .001 in or

Hybrid .01 mm. Use this to enlarge

the Clip Region. The base location of the region is defined by read cell

and timing mark number, measured to response position centers. You can

then enlarge the region in increments of either thousandths of an inch

or hundredths of a millimeter on both the X and Y axes.

+X (.001"

or .01 mm) – valid values are 0 – 1000 for thousandths of an inch,

and 0 – 2540 for hundredths of a millimeter.

+Y (.001"

or .01 mm) – valid values are 0 – 1000 for thousandths of an inch,

and 0 – 2540 for hundredths of a millimeter.

Upper Left/Upper Right – these controls refer to which

corner of the region is being enlarged.

Lower Right/Lower

Left – these controls refer to which corner of the region is being

enlarged.

Create Button

This button is available in the Create

New Grid dialog. Click Modify to accept the Grid Measurement settings

and close the dialog.

Modify Button

This button is available in the Modify

Grid Measurement dialog. Click Modify to accept the Grid Measurement

settings and close the dialog.

Special Cases for Units of Measurement

OpScan iNSIGHT 2/4 (with Imaging) Scanners

As absolute Units of Measurement (.001 in and .01

mm) is an advanced feature of ScanTools Plus software, utilizing the full

capabilities of OpScan iNSIGHT 2/4 (with Imaging) scanners, you should

ensure that your scanner includes the advanced features in scanner Manufacturing

Level ML013 or greater.

To verify your scanner Manufacturing Level, look

at the serial number label on the back of the scanner and read the “ML”

number.

If the ML number is less than ML013,

call Scantron Customer Support at 800-338-5544 to arrange to have your

scanner enhanced to this Manufacturing Level.

For International users, contact your local sales

representative.

Forms Without Timing Marks

If you are using forms

without timing marks, you must use an absolute Unit of Measurement

(.001 in or .01 mm) to specify Evaluate Region and Clip Region locations.

Cell/TM and Hybrid Units of Measurement cannot be used since they require

the presence of timing marks. This includes grayboxes, software bar codes,

and ICR/OCR grayboxes (if you have installed the RealTime Character Recognition

optional component).

iNAME Scan-Time Archiving

If you are using iNAME

image archiving, sparse clipping of grayboxes or software bar codes

is not compatible with use of absolute (.001 in or .01 mm) or Hybrid units

of measurement:

- If any of the

Selected Images to Archive

specified in the iNAME Configuration are for sparse clips of grayboxes

or software bar codes that use an absolute Unit of Measurement (.001 in

or .01 mm), iNAME will fail at scan time ("Problem taking clips"

error) and scanning will terminate.

- If the Selected

Image to Archive is for a sparse clip of a graybox or software bar code

that uses Hybrid Units of Measurement, iNAME will use only the Cell/TM

Position values for the clip. The Hybrid Offset values will not be used.

iNAME is compatible if the Selected Image to Archive

is for a whole sheet clip of any sheet in an application that has a graybox

or software bar code that uses an absolute (.001 in or .01 mm) or Hybrid

Units of Measurement.

OMR/Merge Horizontal Adjustment

No horizontal adjustment is made for background

form merging if you use absolute Units of Measurement (.001 in or .01

mm) for the locations of Standard Graybox, ICR/OCR Graybox, or software

bar code Evaluate Regions and Clip Regions. You must use Cell/TM Position

Units of Measurement.

ScanFlex

No horizontal adjustment is made for background

form merging if you use absolute Units of Measurement (.001 in or .01

mm) for the locations of Standard Graybox, ICR/OCR Graybox, or software

bar code Evaluate Regions and Clip Regions. You must use Cell/TM Position

Units of Measurement. To accommodate this, we recommend you:

- Use dropout

colors for lines, boxes, and text in a form area that is resolved

as a Standard Graybox, ICR/OCR Graybox, or software bar code. See ScanFlex

Form Design Rules.

- Define a larger

Evaluate Region and Clip Region to make sure the entire area is included.

User Exits

User exits

are not compatible with applications that contain grayboxes or software

bar codes that use absolute (.001 in or .01 mm) or Hybrid units of measurement:

- If the user

exit examines a graybox or software bar code absolute Unit of Measurement

(.001 in or .01 mm), it will interpret it as an invalid value.

- If the user

exit examines a graybox or software bar code Hybrid Unit of Measurement,

it will use only the Cell/TM Position values for the clip. The Hybrid

Offset values will not be used.

User exits are compatible with applications that

contain grayboxes and software bar codes that use Cell/TM Unit of Measurement

or that do not examine the graybox or software bar code Unit of Measurement

values.

Related topics

Related topics